High-Powered Catapult Design Principles

Contoh desain catapult dengan daya lwnting tinggi – Designing a high-powered catapult requires a deep understanding of projectile motion and mechanical advantage. Optimizing for range and velocity involves careful consideration of several interconnected factors, from the catapult’s design to the materials used in its construction. The ultimate goal is to maximize the energy transferred from the catapult’s stored potential energy to the projectile’s kinetic energy.

Fundamental Physics Principles

The range and velocity of a projectile launched by a catapult are governed by fundamental physics principles, primarily projectile motion and energy transfer. The range is determined by the initial velocity and launch angle, while the velocity is directly related to the amount of energy imparted to the projectile. Factors like air resistance and gravity also significantly influence the trajectory.

A higher initial velocity, achieved through efficient energy storage and release mechanisms, translates to a greater range, assuming an optimal launch angle (typically around 45 degrees for maximum range in ideal conditions). The energy transfer efficiency depends heavily on the catapult’s design and the materials used.

Catapult Types and Power Output

Several catapult types exist, each with unique strengths and weaknesses regarding high-power output. Traction catapults utilize a rope or chain pulled back to store potential energy, which is then released to launch the projectile. While relatively simple to construct, they are generally less powerful than other types due to limitations in storing significant energy. Torsion catapults, on the other hand, store energy by twisting strong, elastic materials, such as wood or bundles of rope.

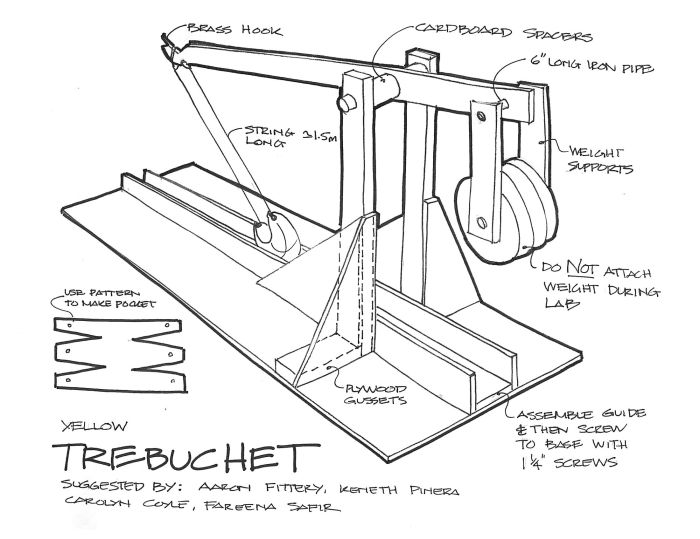

This method allows for higher energy storage and consequently higher projectile velocities, making them suitable for high-power applications. Counterweight catapults leverage gravity to generate power. A heavy counterweight is raised, storing potential energy. Releasing the counterweight converts this potential energy into kinetic energy, launching the projectile. Counterweight catapults are capable of launching heavy projectiles with considerable force, making them particularly effective for siege warfare historically.

The choice of catapult type depends on the desired power level, complexity of construction, and the size and weight of the projectile.

Designing a high-powered catapult requires careful consideration of leverage and materials. The structural integrity is paramount, much like ensuring a protective case for your phone; consider the detailed examples available for designing a rear case for your Xiaomi Mi 8 Lite, such as those found on this website: contoh desain case belakang mi 8 lite. Understanding the principles of effective protection in both scenarios, whether it’s a phone case or a catapult’s structure, is key to successful design.

Material Selection for High-Power Catapults, Contoh desain catapult dengan daya lwnting tinggi

Material selection is critical for building a high-powered catapult. The chosen materials must possess a high strength-to-weight ratio, sufficient elasticity (for torsion catapults), and excellent durability to withstand the stresses of repeated launches. Compromises often need to be made between these properties and cost.

| Material | Tensile Strength (MPa) | Elasticity (Young’s Modulus, GPa) | Cost (Relative) |

|---|---|---|---|

| Bamboo | 100-200 | 10-20 | Low |

| Ash Wood | 80-120 | 10-15 | Medium |

| Steel | 200-1000+ | 200 | High |

| High-Strength Composites (e.g., Carbon Fiber) | 1000-3000+ | 100-300+ | Very High |

The table provides a comparison of four common materials. Note that the values for tensile strength and elasticity can vary significantly depending on the specific type and treatment of the material. Cost is a relative measure, as actual prices fluctuate with market conditions. For instance, while steel offers high strength, its weight can be a disadvantage in some catapult designs.

High-strength composites offer exceptional strength and light weight, making them ideal for high-performance applications, but they come at a significantly higher cost. Bamboo, being a readily available and relatively inexpensive material with reasonable strength, is often chosen for simpler catapult designs.

Design Optimization for High Power: Contoh Desain Catapult Dengan Daya Lwnting Tinggi

Optimizing a catapult for high power involves a careful balance of several key design parameters. The goal is to maximize the projectile’s launch velocity while maintaining structural integrity and control. This requires a systematic approach, combining theoretical understanding with practical experimentation. The following steps Artikel a process for designing a high-powered catapult, focusing on achieving maximum power transfer and projectile range.

A high-powered catapult design necessitates a precise understanding of the interplay between various components. The design process itself should be iterative, allowing for adjustments based on testing and data analysis. Accurate calculations and material selection are crucial for safety and performance.

Step-by-Step Design Process for a High-Powered Catapult

The design process begins with defining the desired projectile weight and range. This determines the required energy storage and power transfer mechanisms. Next, we select appropriate materials based on strength, weight, and cost considerations. Then, we proceed with detailed calculations to determine optimal dimensions and component specifications. Finally, iterative testing and refinement are crucial to optimize performance.

- Define Requirements: Specify the desired projectile mass (m), launch range (R), and maximum launch angle (θ). These parameters dictate the required initial velocity (v₀) using projectile motion equations. For example, targeting a 1 kg projectile with a 100-meter range at a 45-degree launch angle necessitates a considerable initial velocity calculation, requiring substantial catapult power.

- Material Selection: Choose strong, lightweight materials for the arm(s), sling, and frame. Consider factors like tensile strength, stiffness, and fatigue resistance. High-strength woods like ash or hickory, or even lightweight metals like aluminum alloys, could be appropriate choices. The sling material should be durable and capable of withstanding high tensile forces.

- Arm Design and Dimensions: Determine the arm length (L), considering the trade-off between power and launch angle. Longer arms generally store more energy but may be less efficient in power transfer. The arm’s cross-sectional design is also crucial for stiffness and weight optimization. Detailed calculations using beam bending theory are essential to ensure the arm can withstand the stresses during launch.

- Counterweight Design: Calculate the required counterweight mass (M) based on the desired launch energy. The counterweight mass should be carefully balanced to provide sufficient potential energy for launching the projectile without compromising the catapult’s stability. The center of gravity of the counterweight should be accurately determined for optimal energy transfer.

- Sling Design: The sling’s length and material directly impact the projectile’s trajectory. A longer sling can increase the launch velocity, but excessive length can lead to instability and reduced accuracy. The sling material must be strong and flexible to effectively transfer energy to the projectile.

- Testing and Refinement: Construct a prototype and conduct a series of tests to measure launch velocity, range, and accuracy. Adjust the design parameters based on the test results. Data logging and analysis are crucial for iterative improvement. This stage might involve modifying arm length, counterweight mass, or sling design based on the results.

Impact of Design Parameters on Catapult Performance

The performance of a catapult is highly sensitive to the interplay of arm length, sling length, and counterweight mass. Precise calculations and iterative adjustments are crucial to optimize the catapult for maximum power and range.

- Arm Length: Longer arms store more potential energy, leading to higher launch velocities. However, excessively long arms can become less efficient due to increased bending and structural limitations. The optimal length depends on the material properties and the desired launch energy.

- Sling Length: The sling length influences the projectile’s velocity and trajectory. A longer sling can impart more velocity but may also reduce accuracy. The optimal sling length depends on the arm length and the desired launch angle.

- Counterweight Mass: The counterweight mass directly relates to the potential energy stored in the catapult. A heavier counterweight provides more launch energy but also increases the overall weight and complexity of the design. The optimal mass is a balance between energy storage and practicality.

Comparison of Arm Designs

Different arm designs offer varying advantages and disadvantages in terms of power transfer efficiency. The choice depends on factors like the desired power, complexity, and material availability.

| Arm Design | Advantages | Disadvantages | Power Efficiency |

|---|---|---|---|

| Straight Arm | Simple design, easy to manufacture | Lower energy storage compared to curved arms, potential for instability at higher power levels | Moderate |

| Curved Arm | Higher energy storage capacity, smoother power transfer | More complex design, requires more precise manufacturing | High |

| Segmented Arm | Modular design, allows for adjustments and optimization, can handle higher stresses | More complex design, higher manufacturing cost | High (potentially highest with optimized segmentation) |

Question Bank

What are the safety precautions I should take while building and using a catapult?

Always wear safety glasses. Ensure the catapult is built on a stable surface, away from people and obstacles. Use appropriate tools carefully and never exceed the catapult’s design limits. Test in a controlled environment.

How can I increase the accuracy of my catapult?

Accuracy depends on consistent launch parameters. This includes consistent projectile weight and launch angle. A well-aligned and stable structure is also crucial. Practice and fine-tuning are key.

What are some common mistakes to avoid when building a catapult?

Using weak or inappropriate materials, poor construction leading to structural instability, neglecting friction reduction techniques, and inaccurate measurements are common pitfalls.